|

Separation Techniques personnel have designed numerous plants for a broad range of applications, for clients around the world. Separation Techniques personnel have designed numerous plants for a broad range of applications, for clients around the world.

Applications vary enormously, ranging from isolation and recovery of components in the biotechnology and medical industry to whey demineralisation as well as deionisation and decolourisation of sugar syrups and fruit juice/ fruit alcohol processing.

SepTech’s expertise in the area of process technology for the food industry enables them to produce designs which will ensure a high quality, high value end-product.

Our juice systems utilise a hygienic column design with perforated plate distributors. To prevent the formation of off flavours within the resin bed and column all stagnant /dead areas have been eliminated from the design. Even flow over the entire bed area with the minimum of mixing volume to minimise the use of regenerants and maximise the efficiency of the loading cycle has been achieved in our unique systems.

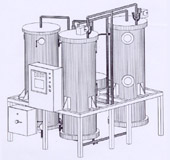

Our juice systems typically process 10-15 m3/hour of juice with a 2 m3 resin volume. As the design is modular higher processing flow rates can be accommodated if required. As the physical size of juice systems tends to be relatively small the columns are skid mounted with all associated regenerant and backwash facilities.

An example is sugar decolourisation.

Syrup enters the column through a surface distributor; the colour is adsorbed onto the resin and the decolourised syrup taken off by the bottom distributor. At the end of a loading cycle, rinse water is used to displace partially treated syrup from the resin bed; "sweetening off". Regenerant is then passed through the bed, initially displacing the water, to desorb the colour from the resin. Rinse water then displaces regenerant and is in turn displaced by syrup; "sweetening on", for the commencement of a new loading cycle.

A number of factors determine the relative efficiency of this process, including the sweetening on/off time and volume, syrup dilution (evaporation costs), strength and volume of regenerant (chemical/ running costs) and rinse water requirement (effluent).

Separation Techniques optimise these factors in this application by good distribution, level control and extensive process experience.

Separation Techniques achieve this by good engineering designs, enabling full utilization of the bed and its cleaning and accurate process control. Optimising the column hydraulics and ensuring that the resin beds in our columns are utilised efficiently throughout the operational cycle of the plant are the key to a successful operational plant.

|